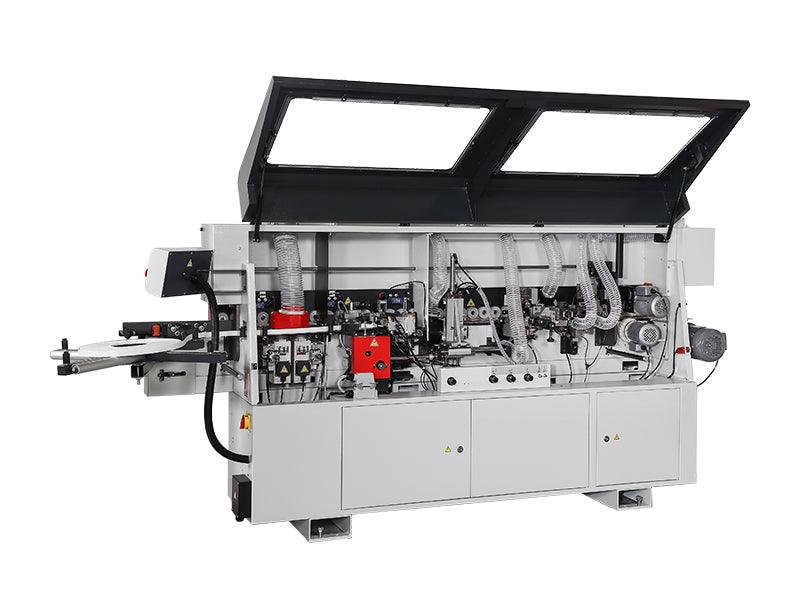

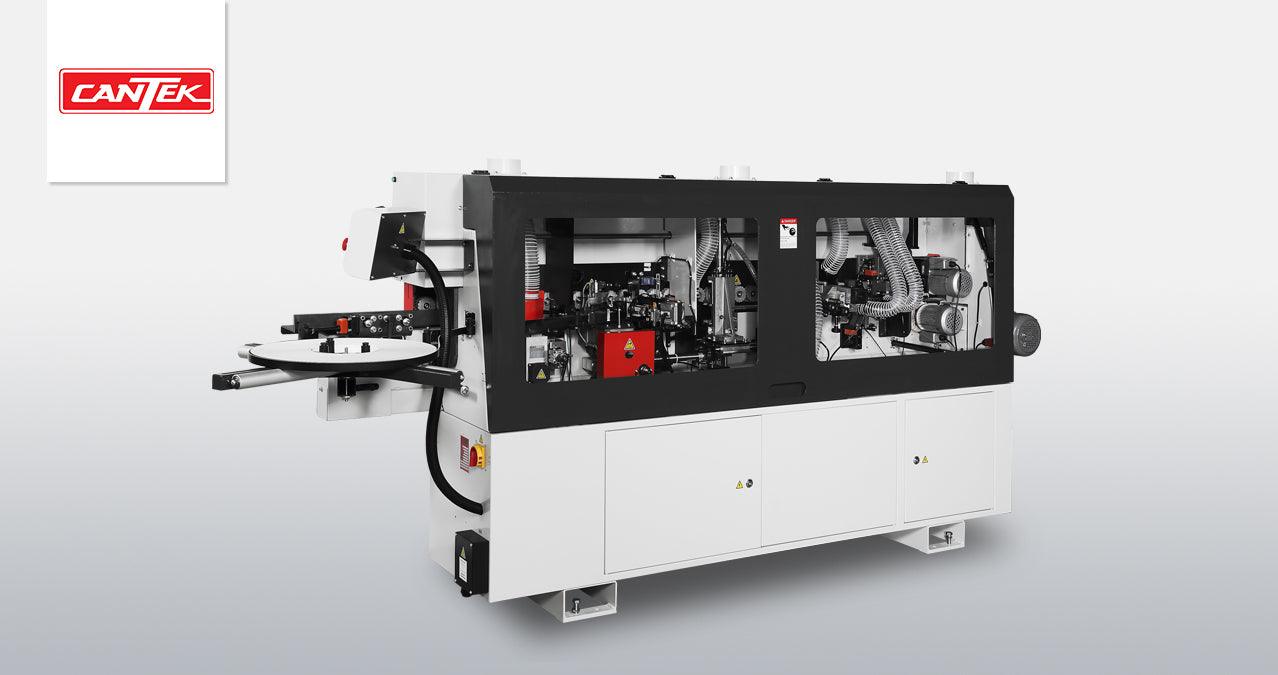

CANTEK Automatic Edgebander with Premilling MX350

by Cantek

Original price

$33,900.00

-

Original price

$33,900.00

Original price

$33,900.00

$33,900.00

-

$33,900.00

Current price

$33,900.00

![]()

The MX350 from Cantek is designed to be a compact, and durable edgebander offered at an affordable price. This machine is equipped with premilling, end trimming, flush trimming, PVC scraping, and buffing. User friendly controls and adjustments allow for efficient changeovers of edge tape thicknesses between 0.4mm & 3mm.

- PLC control system with LED display and keypad

- Work-piece is fed by chain

- Edge coil support plate: Ø 800mm (31 1/2″), for PVC/ABS

- Edge feeding is Automatic edge feeding with a thickness capacity of 0.4–3 mm; strip material can be hand-fed

- Coiled edge bands up to 3 mm in thickness in Hard-PVC/ABS are cut with guillotine shears.

- Teflon-coated hot-melt glue pot

- Spring loaded pressure unit with (2) pressure rollers

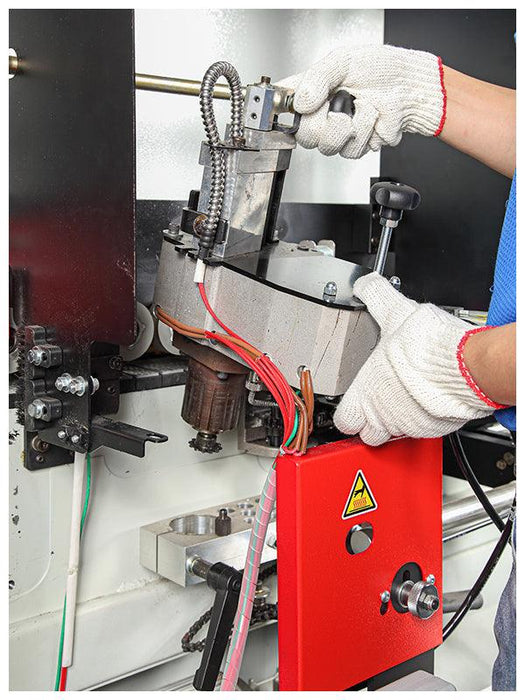

- Pre-milling function can remove up to 3mm and is designed to provide an ideal edge for applying edge tape by cleaning up poorly cut panels. Consist of (2) counter rotating diamond cutterheads for optimum cut results.

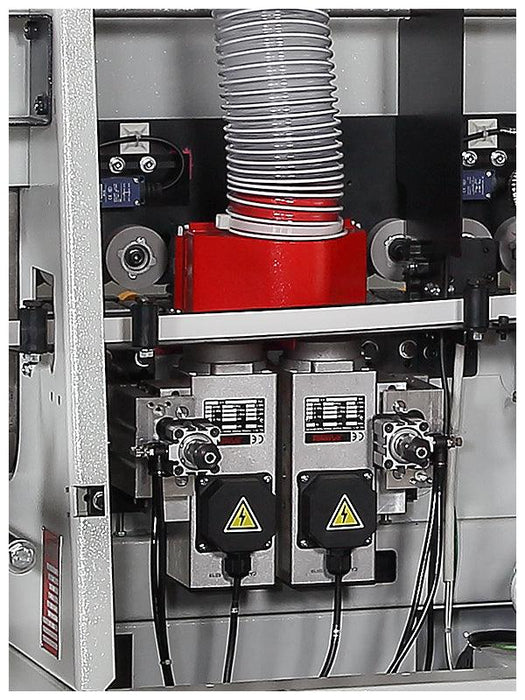

- High frequency 12000 RPM end trimming unit, with Ø100 mm (4″) TC-Saw blades

- High frequency 12000 RPM top & bottom trimmers with insert knife cutters for radius trimming & bevel trimming

- Radius scraper with 2mm radius

- 3000 RPM top & bottom buffing units

- Heavy duty pressure beam with extendable work-piece support

- Heated infeed fence for pre-heating the panel for optimum glue penetration

Feeding speed 9 meters/min. (29.5 FPM) Panel thickness 8~45 mm (0.315″~1.77″) Max. premill thickness 32mm (1.25″) Edge thickness 0.4 ~ 3 mm (0.0158″~0.118″) Min. panel width 100mm (4″) Min. panel length 170mm (6.7″) Working table height 850mm (33.47″) Dust collection outlet Ø 127 mm (5”) x 2 Electrical consumption 7.5 KW (10HP) Electrical requirement 40 AMPS @ 230/3/60 Machine weight 660 kgs (1452 lbs) Shipping dimensions 3450x660x1850mm (114″x30″x54″) Shipping weight 708 kgs (1558 lbs) Voltage 230/3/60 (Voltage must be +/- 5%)

Feeding motor 0.75 kW Pre-milling motors (2 pcs) 1.1 kW each (12000 RPM) Glue spindle motor 0.18 kW Front/rear trimming motor 0.22 kW (12000 RPM) Upper trimming motor 0.37 kW (12000 RPM) Lower trimming motor 0.37 kW (12000 RPM) Upper buffing motor 0.12 kW (3000 RPM) Lower buffing motor 0.12 kW (3000 RPM) Pre-heating 0.4 kW Glue pot 1.315 kW

Operating panel with LED keypad

- Glue temperature settings

- Units can be selected and disengaged individually

- Heated fence is standard

Edge feeding for coiled materials

- Edge feeding is automatic for roller materials with a thickness of 0.4–3 mm

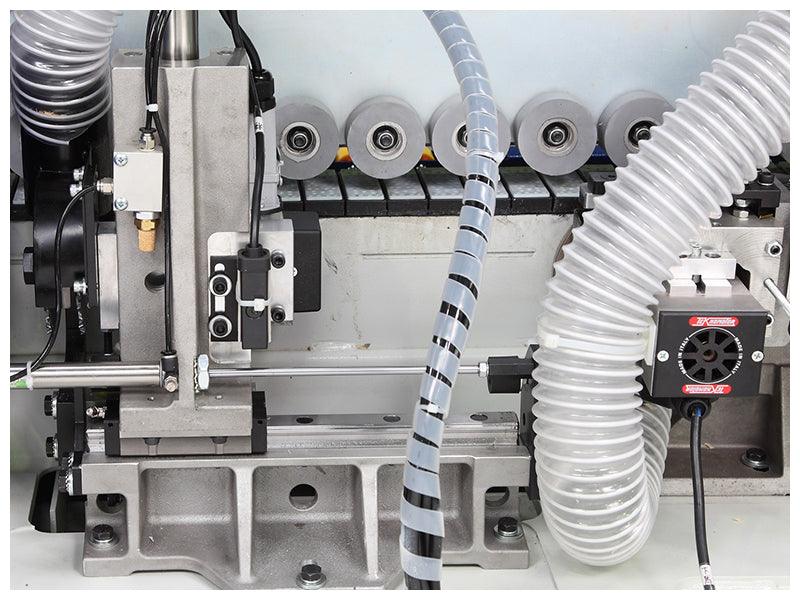

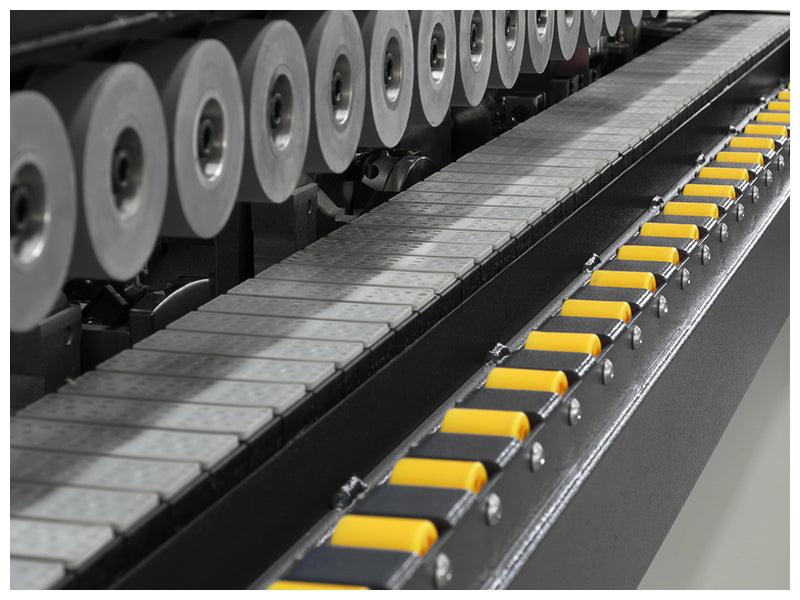

Heavy-duty chain feeder

- The steady work-piece feeding mechanism is comprised of a chain and set of drive rollers, which will not scratch the work-piece surface.

Pre-Milling Unit

- (2) counter rotating cutterheads for removing up to 1mm of the panel edge to produce an optimum edge for applying the edge tape. This is designed to clean up edges which are poorly machined.

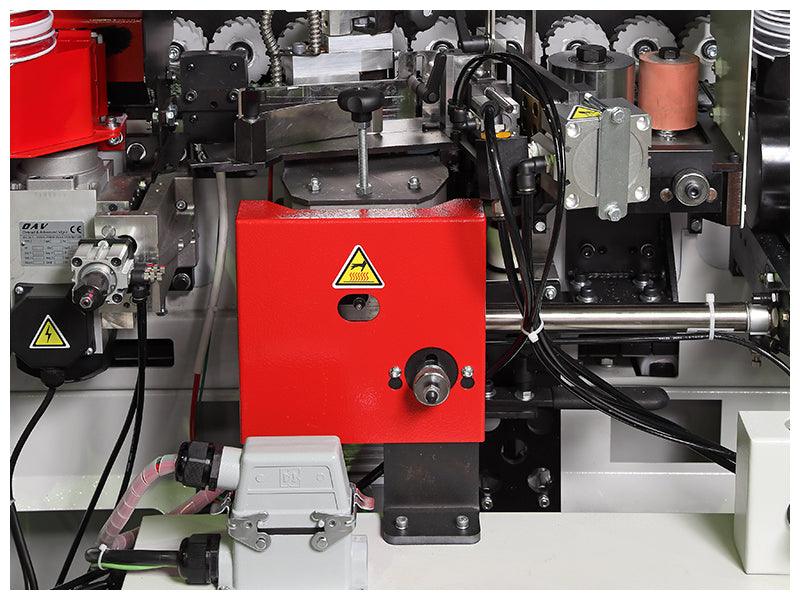

Glue Pot

- The 1.2 kg Teflon-coated glue pot is designed for EVA hot-melt glue. The glue is applied by a roller and the glue amount is adjustable

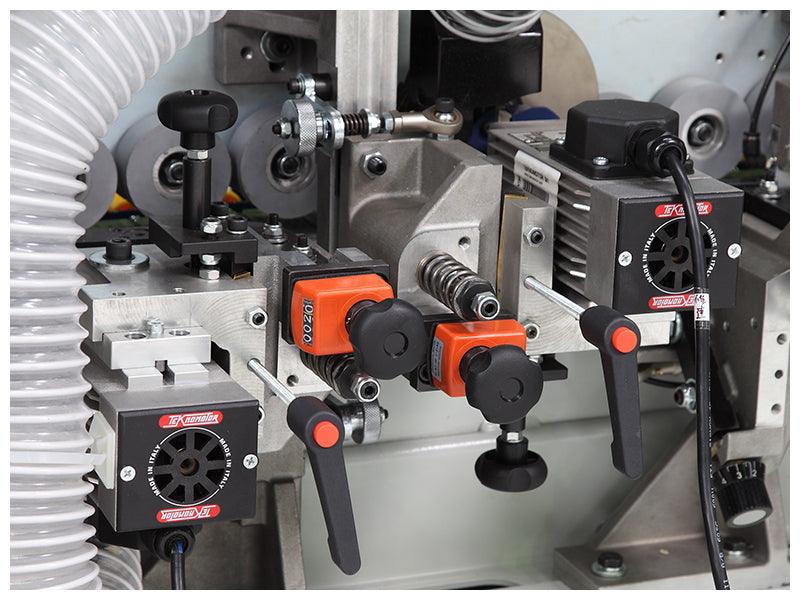

Pressure Roller

- The pressure roller unit consists of one large roller, followed by a smaller one. The purpose of the unit is to improve the glue bond between the edge and the material. The unit is mechanically spring-loaded and due to the “Quick” setup system, can be adjusted exactly to the required edge thickness. The adjustable spring system allows for a perfect bond between the panel and edge every time.

Guillotine Shears

- Coiled material up to 3 mm in thickness can be trimmed by the guillotine shears.

End Trimming Unit

- Mounted on high-precision linear bearings, which ensure perfect cutting results for years to come. The high frequency 12000 RPM motor meets any challenge, regardless of edge type and thickness.

Flush and Radium Trimming Unit

- The biggest advantage of the new multi-functional combination unit is the amount of space it saves in the machine. The adjustment of the settings from flush to beveled finish for thin edges, as well as radius trimming for thicker edges, is quick and easy. TC 2 mm radius tooling is included as standard.

Scraping Unit – Radius Scraping Unit

- The scraping unit fine-tunes the edge radius while removing knife marks left on during the milling process on 2mm & 3mm edging.

Buffing Unit

- The buffing unit leaves a super finish on ABS and PVC edging, and removes any discoloration on the edges, which is especially noticeable when working with dark edge material.

Panel Thickness Setting

- Panel thickness adjustment is quick and accurate & is achieved by a handwheel with digital readout.